Friends who do investment casting know that this business is all about "details determine success or failure". Customers may want aircraft blades, medical equipment or precision instrument parts, and a difference of 0.01 mm may make the product scrapped. Today, let's talk about how to achieve the accuracy of castings.

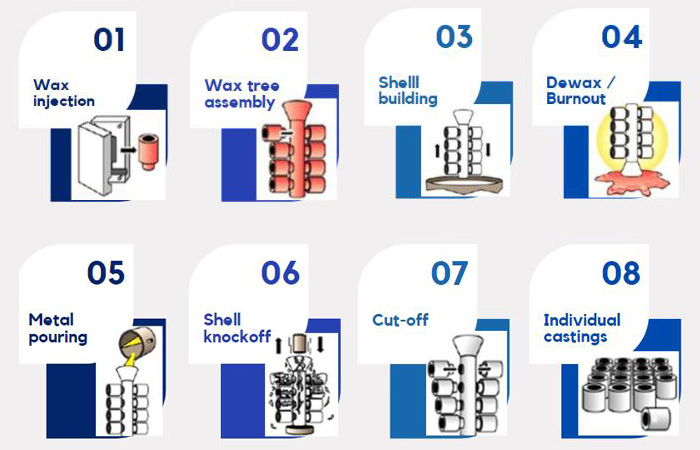

1. Wax model making - the "first pass" of accuracy

The wax model is like the "gene" of the casting. If this step is crooked, all the rest will be in vain. Now the mainstream uses 3D printing wax models, and the accuracy of light-cured resin can reach ±0.05mm, which is much better than traditional hand-carving. But pay attention to temperature control. If the workshop temperature differs by 5℃, the shrinkage rate of the wax model can be erratic. It is recommended to use constant temperature and humidity equipment, don't save this little money.

2. Shell making process - don't let the ceramic shell "pit" you

How many layers of silica sol paint are applied and how thick each layer is directly affects the final size. One factory was lazy and brushed one less layer, resulting in sand holes all over the surface of the casting. Now it is popular to use "gradient shell making" - fine powder for the inner layer and coarse powder for the outer layer, which can not only ensure smoothness but also reduce stress deformation. Remember to dry the shell for a long time, otherwise it will "explode" directly during dewaxing.

3. Melting and pouring - the "temper" of the molten metal must be understood

The shrinkage rate of stainless steel and high-temperature alloy can differ by 1%! The mold size must be adjusted according to the material properties. The pouring temperature is even more critical. A certain aviation parts factory directly scrapped the casting because the temperature was 20℃ higher and the grain size was coarse. Now we use mold flow analysis software to simulate in advance, which is much more reliable than trial and error.

4. Post-processing - grinding is not based on brute force

It is more stable to use robots to grind the burrs of investment castings than manual work, but the programming is fine. I have seen people use large grinding wheels to save trouble, but they grind through the thin-walled parts. "Magnetic grinding" is popular now. Small parts are rounded by themselves in the magnetic field, and the accuracy can be controlled to ±0.02mm.

5. Inspection methods - don't wait until shipment to "open the blind box"

Three-coordinate measuring machine is standard, but don't forget X-ray flaw detection. There was a factory that made turbine blades. The surface inspection was all qualified, but the X-ray found internal pores and almost lost the customer's order. Now even AI visual inspection is used, which is faster than the human eye and does not make mistakes.

Conclusion:

In the final analysis, the accuracy of castings is achieved by a whole set of "combination punches". From wax molds to inspections, every link must be taken seriously. Now the market competition is so fierce, whoever can get an extra 0.01mm in accuracy can take high-end orders. Next time the customer asks "how to ensure accuracy", just throw this article to him - professional matters must be solved with professional methods.

As a professional manufacturer and supplier, we provide high-quality products. If you are interested in our products or have any questions, please feel free to contact us.

Most of our quotes are delivered within 24/36 hrs. and usually in much less time, depending on project details.

Our team will contact you directly about your CNC machining quote to ensure you’ve received and understand all aspects of your quotation and to answer any questions you may have about your options.